Repair and reconstruction of all types of electric machines

With three decades of experience in the field of overhaul of electric motors and generators, Roshd Sanat Niroo Company (RSN)has been able to provide a wide range of services to various industries in the country, including mines and metals, oil and gas and petrochemicals, water and electricity industry, cement industry, etc.

Relying on engineering power and specialized and experienced personnel, and using the latest global equipment and standards, this company is able to test, troubleshoot, overhaul, repair and manufacture spare parts for all types of electric motors and high and low voltage generators.

Manufacture and replacement of coils

Medium and high voltage electric motors and generators use a set of coils which are commonly called form wound.

Roshd Sanat Niroo Company (RSN)owns complete equipment for manufacturing medium and high voltage coils up to 18 kV level without any limit in size and power. Coils are made in a clean room, free of dust and metal contaminants and using high quality insulation produced by leading European brands. VPI (Vacuum Pressure Impregnation) technology is utilizes to produce and replace new coils, and Resin Rich technology can be implemented if needed.

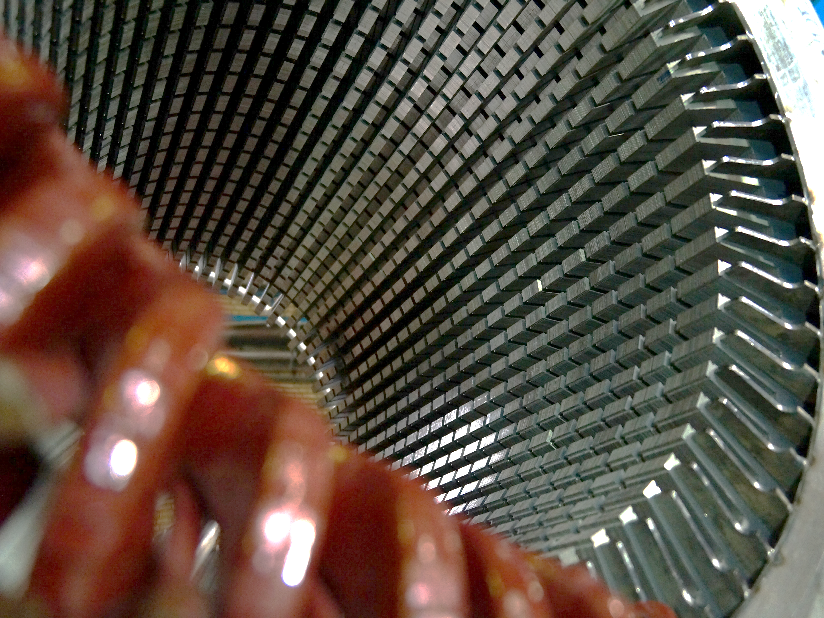

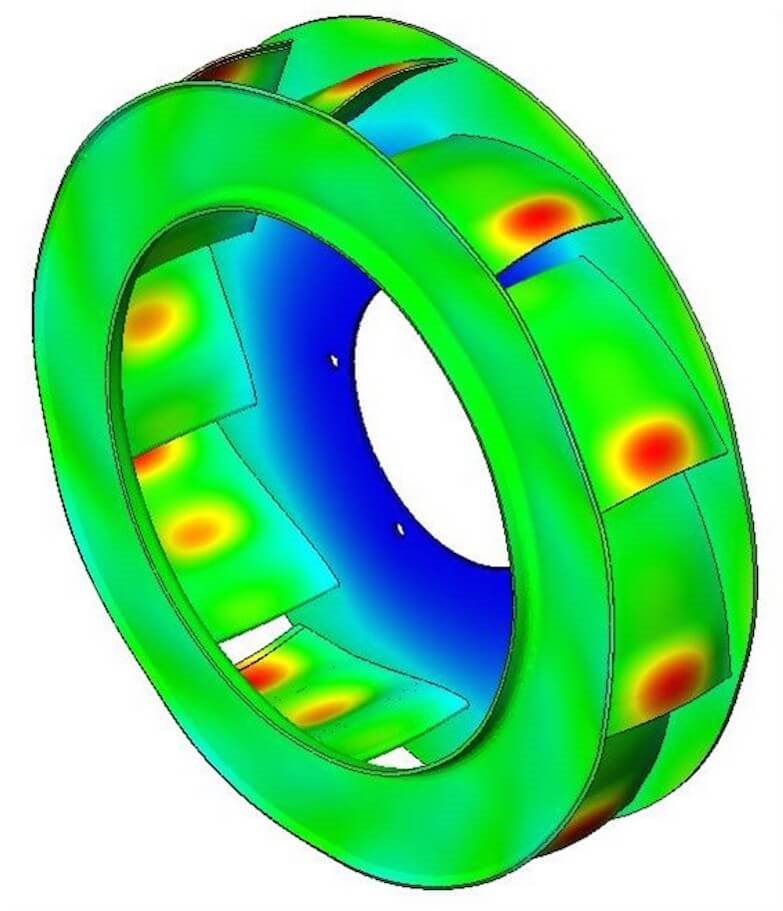

Construction and replacement of rotor and stator cores

In some cases, due to high stress and long time operation, the insulation quality of the core sheets decreases and the losses increase, which leads to an increase in the operating temperature of the electric machine and a decrease in efficiency. It is also possible that part of the core is defective due to arcing, or the rotor contacts with the stator and leads to damage to the core sheets due to mechanical defects such as bearing and housing failure or broken shaft. To repair the core laminations, local methods such as acid washing and polishing can be used, and if the volume of damage is substantially high, the core penetration method can be used. But in some cases, the amount of damage is such that all or part of the rotor or stator core must be replaced.

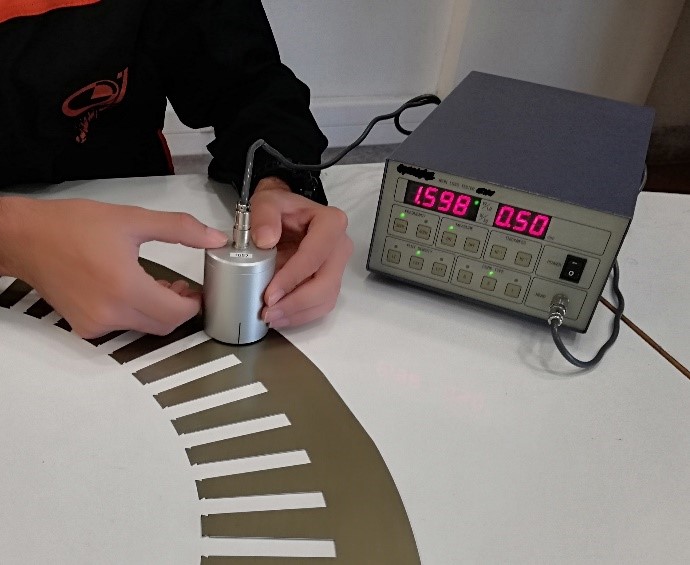

The process of repairing and testing the core is performed using best updated methods. In case of need to build and replace the core laminations, the grade of the original core sheet is determined by using the core loss measuring device, then newly manufactured core sheet with less losses or the same grade of the original sample will be applied. Roshd Sanat Niroo Company, according to customer request, will fabricate and apply alternative core sheets with less heat loss than the original sample to improve the operating temperature of the electric machine and increase its efficiency.

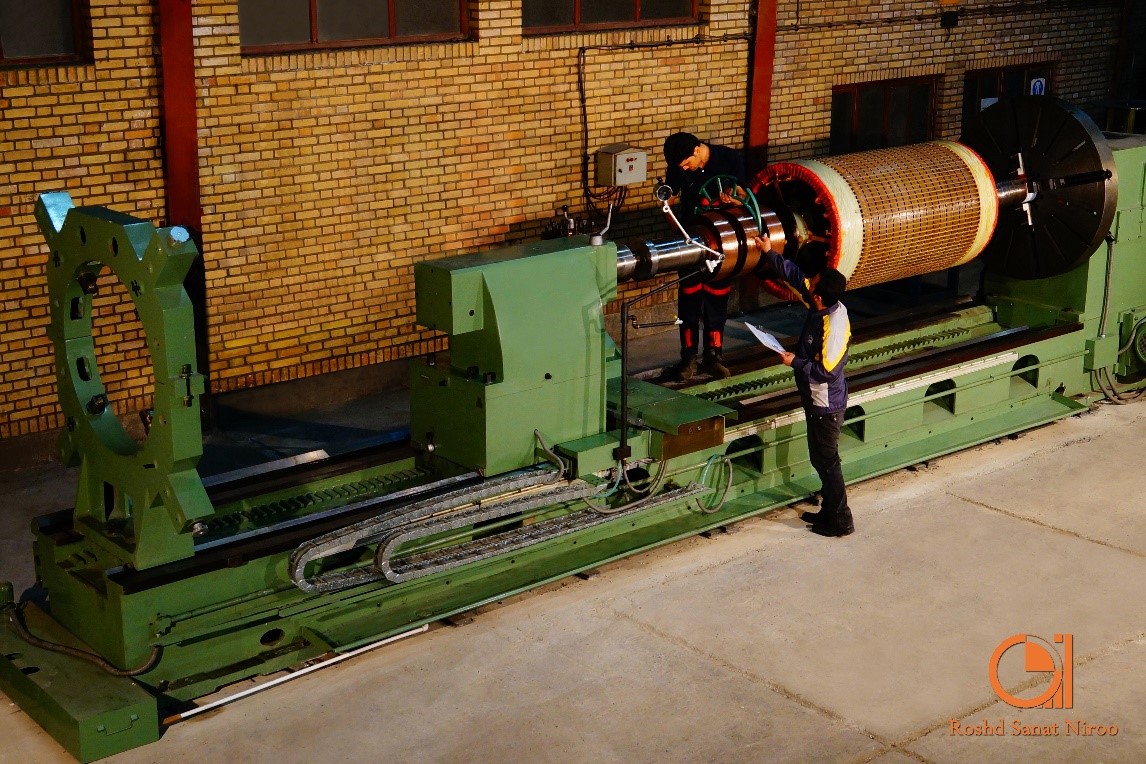

Shaft repair and construction

The shaft or axis is one of the main parts of any rotary electric machine. Due to excessive operation or the application of abnormal stresses or possible installation errors etc., size change, eccentricity or out of roundness may occur in the electromotor shaft. In Roshd Sanat Niroo Company, all mechanical tests and dimensional measurements are inspected and controlled by calibrated dimensional measuring tools.

If the shaft is to be repaired, the material used in the original sample is analyzed and then, build up method is used by welding methods or metal spray with compatible material and finally, the repaired surfaces are re-machined to the dimensional and geometric tolerances.

If the shaft needs to be manufactured and replaced, the material used in the original sample is analyzed and the type of alloy and its hardness is assessed, the new shaft is made and replaced using the same material or a material with higher strength level. All non-destructive tests including Liquid penetration test, Magnetic particle test, Ultrasonic wave test and Visual test are performed during fabrication and welding processes according to related standards.

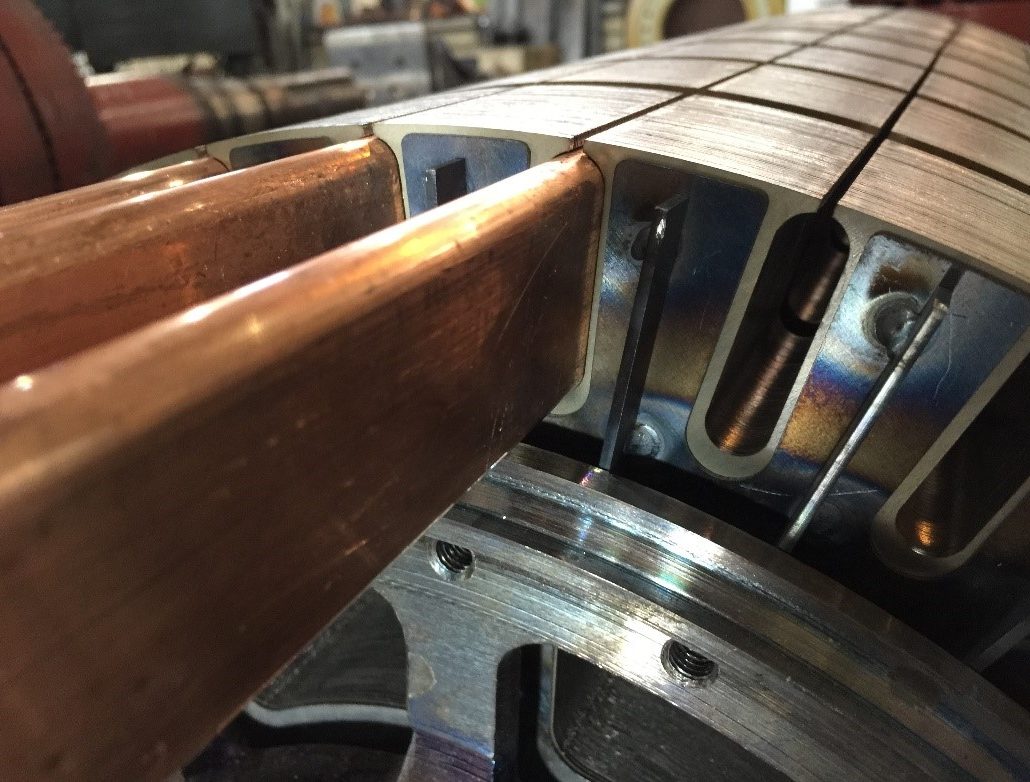

Replacement of rod and rotor short-circuit ring

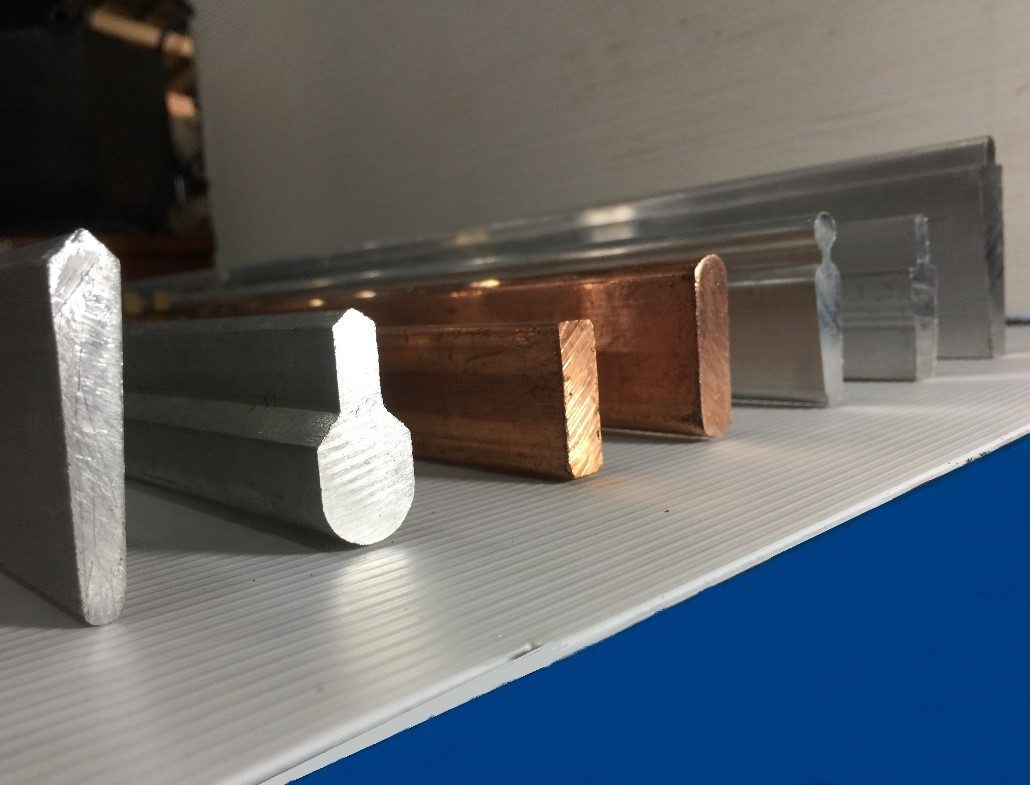

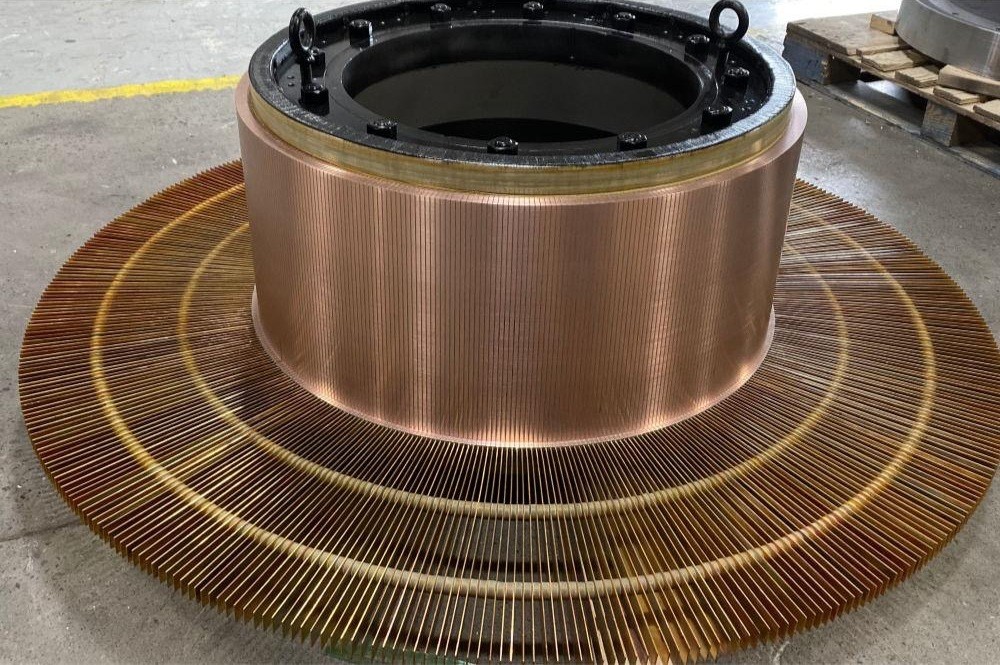

Squirrel cage rotors use aluminum or copper rotor bars. Cracking or failure along the rotor rod or at the connection point to the short-circuiting rings on both sides is one of the defects that lead to failure in electric motors. In such cases, it is necessary to dismantle the old rods and build new rods and assemble them at the rotor core.

RSN manufactures and replaces various types of copper and aluminum rods without any restrictions on their size and cross-section geometry. Welding of the rod to the short-circuit rings on both sides of the rotor is performed by brazing methods for copper rods or welding by GMAW or GTAW methods for aluminum rods.

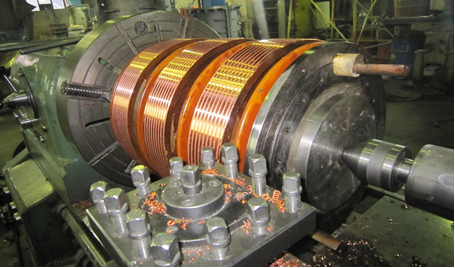

Manufacture, replacement and repair of collectors

The commutators or commutator is a sensitive part of direct current machines that may fail due to various reasons. Common commutators failures in DC electric motors include wear and unevenness of the commutators surface, short circuit between the commutator blades, connection of the commutators body to the shaft, raised blades, arched blades, riser failure, and severe contamination due to excessive carbon brush scrub particles. Each of these defects requires different repair processes that are performed in Roshd Sanat Niroo Company (RSN), without any restrictions on the size and type of commutators, using high quality insulation materials and most recent methods. In some cases, due to excessive wear and tear of the commutators or reduction of the commutator diameter from the minimum allowable size, it is necessary to manufacture a new commutator and replace the previous one.

The commutators are manufactured using oxygen-free copper and high-quality insulating materials and all the electrical and mechanical tests are performed in accordance with world standards at RSN. In addition, the commutators made by RSN are subject to seasoning process which is the most severe type of commutators test with the aim of simulating the worst possible operating and working conditions at maximum temperature and over speed.

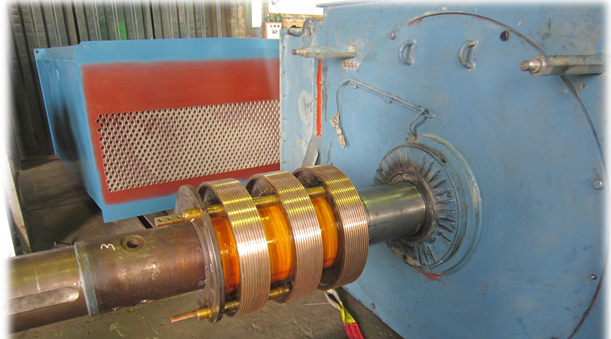

Slip ring is a component used in winded rotor electric motors and some generators that contribute as a part of the rotor electric circuit. Abrasion and poor quality of the slip ring surface will increase the carbon brush consumption rate and as a result, contamination in the slip ring section. Increased level of contamination will reduce the insulation resistance and cause contact between the slip ring and the shaft or short circuit between the slip ring rims, which can cause the stoppage or inefficiency of the electric motor or generator.

In order to prevent these defects, it is necessary the ring slip electric motors be tested and overhauled in less time intervals than squirrel cage electric motors. Washing and dehumidifying the rotor and slip ring, performing electrical and mechanical tests, machining and polishing the slip ring and insulation strengthening are among the routine steps in the overhaul of slip ring electric motors.

RSN repairs and overhauls all types of slip rings and slip ring electric motors without any restrictions on voltage and power in accordance with the related standard methods. If it is needed to manufacture a new slip ring and replace the previous one, RSN uses high quality raw materials and oxygen free copper for the copper rings cases.

There are different heat sources in all electric motors where the cooling system must be able to transfer heat losses with appropriate capacity. Therefore, the cooling systems of electric motors are classified and coded according to IEC60034-6 standard. IC411 – IC511 – IC611 are the most common cooling methods in electric motors. Most cooling systems use a variety of fans, with centrifugal fans being preferred due to better efficiency and less noise.

The material used to fabricate the fans is usually steel or aluminum, and in some cases cast iron. Low-power electromotors may use a variety of polymers as well. The other part of the cooling system is the heat exchanger, which is built-in for IC411 and IC511 electric motors and is considered as a part of the electric motor main frame. But in IC611 electric motors, the heat exchanger is made as a separate part of the electric motor that can be disassembled and assembled on the main frame.

Roshd Sanat Niroo Company (RSN) design and manufacture all kinds of fans and heat exchangers without any restrictions on their type and size. In addition, RSN offer engineering solutions to improve the operating temperature of electric motors with new design and changes in cooling systems to various industries in the country.

Factory

Address: Roshd Sanat Niroo Company, 21st South Street, Hashtgerd Industrial City

Email: factory@roshdsanatniroo.com

Phone: +98 49052, +982644226107

Fax: +982644220260

Central office

Address: No. 23, Shahid Akbari St., 22 Bahman St., Ashrafi Esfahani Highway, Tehran

Email: headoffice@roshdsanatniroo.com

Phone: +98 49052, +982148000981

Fax: +982144424892

All rights belong to Roshd Sanat Niroo Company.