Manufacture of 2.2 MW electric motor for pelletizing mills by domestic manufacturers

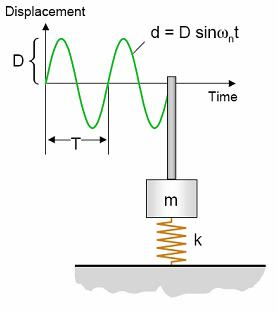

According to the Steel Reporter, Mohammad Khodabandeh, Head of Electrical and instrument Repairs of the Pelletizing Unit announced that: “For the first time, one of the mill motors of Line No. 1 of the Pelletizing Unit was replaced with a domestic motor by installation during the last 13 stoppage (cold line) days successfully brought up to line of operation. Explaining the motors used in each of the pelletizing unit’s mills, he added: “Each of these mills has two 2.2 MW motors with rotation speed of 1000 rpm and a rotor weight of 12 tons, yielding the driving force to rotate the mill container at a speed of 13.9 rpm through a gearbox and pinion.

The mill container with a diameter of 5.2 meters contains more than 200 tons of steel pellets with a size of 30 to 40 mm. According to the interior design of the mill container and its equipment, every hour, 240 tons of grit concentrate that is transformed from 95% granulation under 1 mm to 80% granulation under 45 microns and reaches the appropriate granulation for crude pellet formation.

According to this report, Rahmatollah Soltani, foreman of electrical and instruments repairs of pelletizing unit, also noted: this motor was manufactured domestically instead of foreign one by Roshd Sanat Niroo (RSN) Company in coordination with the spare parts purchase management department and technical office of iron making repair department. During the manufacturing process of this motor, production-line inspections and various performance tests were performed in Roshd Sanat Niroo Plant with the cooperation of the electrical specialists of the pelletizing unit and the technical office of iron making repair and also the spare parts purchase experts. By ensuring the correct operation of the motor, it was transported to Mobarakeh Steel Complex and the necessary planning was performed to install and run the motor at the stoppage of the pelletizing unit in July. This great measure was carried out with the support of the iron making management, follow-up of pelletizing unit personnel, spare parts purchasing management, pelletizing unit repair technical office, the support of the technical inspection manager, constructive opinions of electrical and rotary machinery department and RSN. At the end, it is necessary to thank and appreciate the cooperation of the procurement units, technical inspection, repair office and support of the iron making and procurement managers.

Click to view “Selected Products of Roshd Sanat Niroo Company”